In addition to regulating airflow and maintaining comfortable temperature levels, they also help minimize the transmission of airborne diseases. HVAC systems play a vital role in hospitals and other healthcare facilities. The American Institute of Architects (AIA) further specifies that a minimum of 12 air changes per hour are required for new facility constructions and renovations, while a minimum of six air changes per hour are required for existing facilities. These filtration units are designed to remove 99.97% of airborne particles that are ≥0.3 µm in diameter. AIR CHANGES PER HOUR (ACH)Īs per the infectious disease control guidelines outlined by the Centers for Disease Control (CDC), isolation rooms should have a minimum of 12 air changes per hour using medical-grade HEPA filters. While there are many factors to consider to ensure an isolation room will work properly, some of the key ones include air changes per hour, HVAC, pressure control, temperature control, and supplemental controls. Otherwise, there is an increased risk of cross-contamination between patients, personnel, and visitors. KEY CONSIDERATIONS WHEN BUILDING AN ISOLATION ROOMĭue to their critical function, isolation rooms must be designed and constructed carefully. They are utilized to protect immune-compromised patients from airborne-transmissible infections.

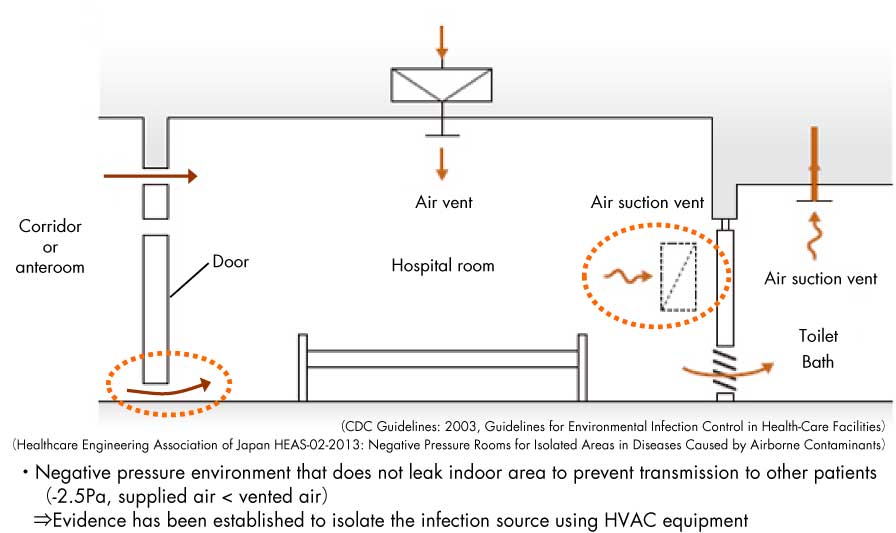

This design prevents airborne infectious particles from entering the room from other areas of the facility. They have higher pressure levels than adjacent rooms so air will rush outward rather than inward when the room is opened. These rooms utilize a positive-pressure differential. They are employed as single-occupancy rooms to isolate patients with suspected or confirmed airborne-transmissible infections. This design prevents airborne infectious particles from escaping into other areas of the healthcare facility. They have lower pressure levels than adjacent rooms so air will rush inward rather than outward when the room is opened. These rooms-also referred to as infectious isolation rooms-utilize a negative-pressure differential. Airborne Infection Isolation (AII) Rooms.While they are generally used for patient contact isolation applications, they can be used for normal patient care when isolation is not required. They have normal HVAC systems and may or may not have a clinical handwash sink, en suite shower and toilet facilities, and a self-closing door. These rooms utilize standard room (neutral) air pressure levels. Isolation facilities can be configured in several ways, including the following: They can achieve this goal in a number of ways, including by controlling the quantity and quality of intake or exhaust air, maintaining an air pressure differential between adjoining areas, directing airflow in a specific pattern, diluting room air with large volumes of clean air, and cleaning the air with high-efficiency particulate air (HEPA) filters. These specialized rooms are designed to decrease the likelihood of cross-infection among people within the facility by controlling the flow of air within the room to reduce airborne infectious particle levels. An important element of a comprehensive infection control strategy is the use of isolation rooms. In hospitals and other healthcare facilities, controlling the spread of infectious diseases is critical to keeping patients, personnel, and visitors safe and healthy. Additionally, we highlight the products we offer that can be used to help build isolation rooms. Healthcare professionals know they can rely on us for products that keep their patients and personnel safe and healthy, such as hospital isolation room systems.īelow, we provide an overview of hospital isolation rooms, outlining the types available and key considerations to keep in mind when building one for a healthcare facility. One of the key markets we serve is the healthcare industry. This extensive experience provides us with the knowledge and skills needed to deliver appropriate systems for a wide range of industries. Personal Forklift Cabin Air Conditioner – Cabin Cool SystemĪt Air Innovations, we’ve designed, manufactured, and tested custom environmental control solutions for OEMs and non-OEMs for over 30 years.Wine Guardian – Low-Temperature Commercial & Residential HVAC.Filter, Pressurize, & Ventilate Air (HEPAiRx® System).IsolationAir® Quarantine Control Systems.Sterile Storage – Temperature & Humidity Controlled Cabinets.

0 kommentar(er)

0 kommentar(er)